A flow sensor refers to a tool used to measure a moving gas or liquid’s quantity. In technical terms, it is called a flow rate measurement. The flow sensors are also known as flow meters. It also has a variety of names based on the industry where they are applied.

In industrial automation, there are several types of flow meters, all of which work differently. An accuracy flow sensor is crucial in medical uses, such as drug delivery. Let us discuss the different liquid flow sensors.

Different Types of liquid flow sensors

Spring and piston flow Sensors

It is one of the most popular sensors that use an annular orifice. The annular orifice has a piston and a tapered cone. At the base of the cone lies the piston held by a calibrated spring. The scales used to depend on the densities of oil and water. The use of densities to gauge flow is simple. That has made them very cheap.

Know more: Must-Know Aspects about a Roosa Master Injector Pump

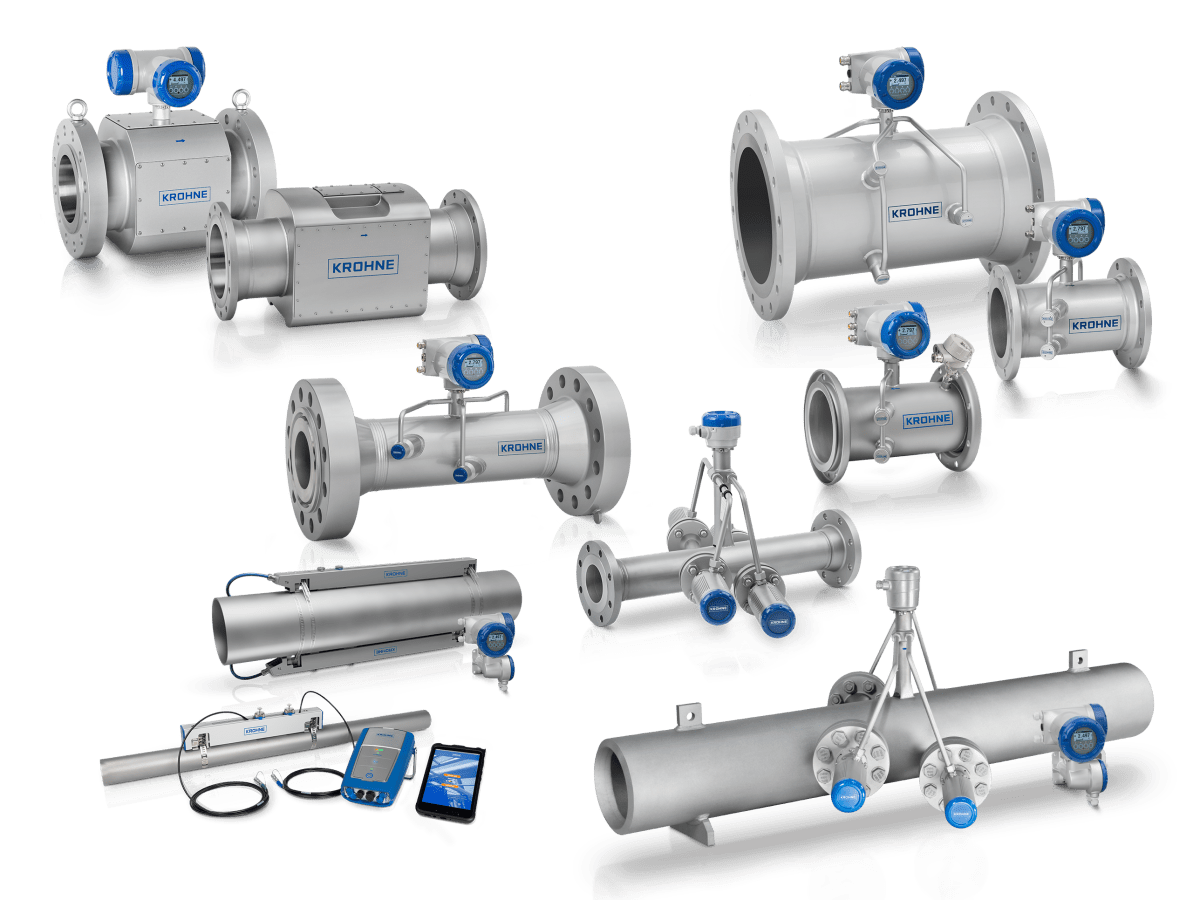

Ultrasonic Flowmeters

The ultrasonic flow meter works on the Doppler Effect. The Doppler Effect is the shift in frequencies of an ultrasonic signal. That occurs when reflected by suspended gas bubbles or moving particles.

A transducer produces a short ultrasound at the end of the tube. The sound wave moves through the liquid at the speed of sound. The faster the fluid travels, the quicker the time of flight.

Ultrasonic flow meters are popular with wastewater and dirty fluids. These sensors can bear up against harsh situations. That is because they don’t get in contact with the liquid. In similar cases, other sensors would break.

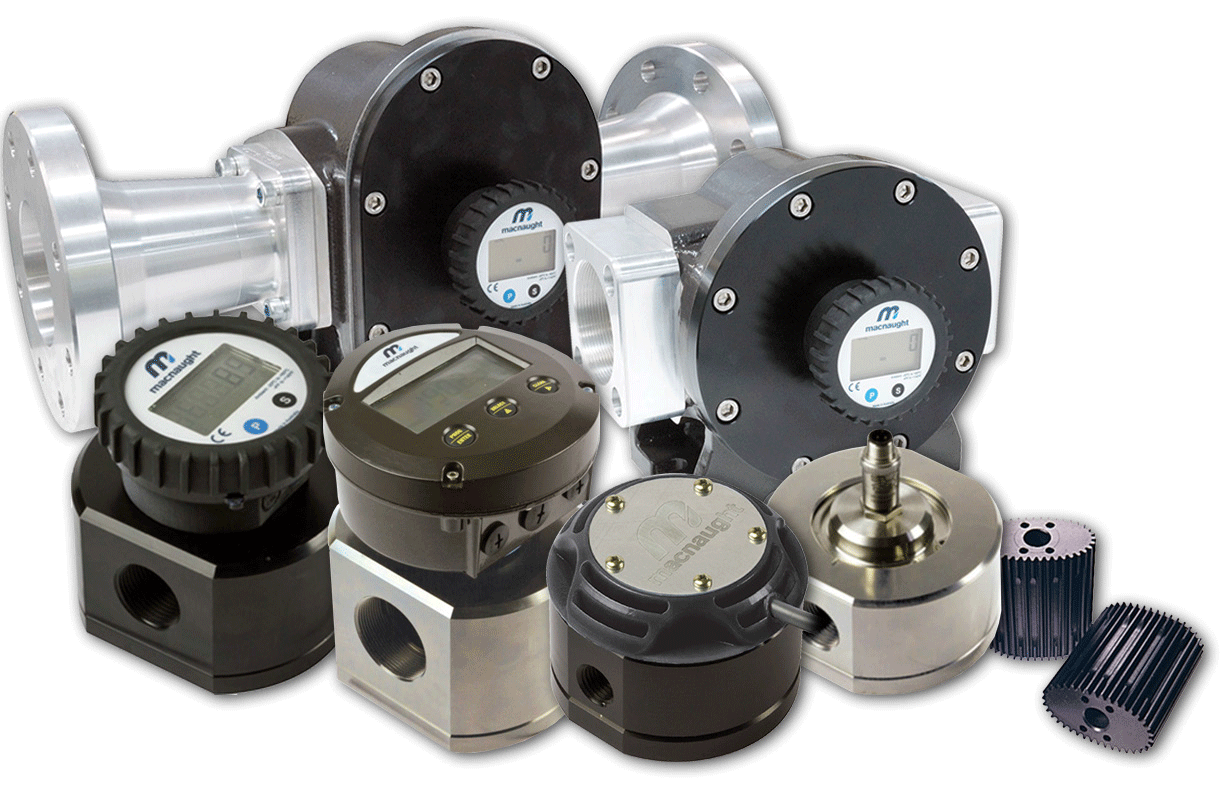

Positive displacement flow meters

Works on a system of dividing fluids into endless and metered amounts. Liquids passing through the sensors are trapped between the sensor’s parts—the liquid moves in a high precision chamber. You can tell the fluid volume by the number of parcels that pass through it. Thus, the flow rate is affected by the speed of the whirls.

The sensor has two popular types. What a variety! There is a system and a complete sensor system. That variety allows you to customize.

Learn more: Way To Get Your Metal Parts Customized

Magnetic Flowmeters

Faraday’s Law is used in liquid flow measurement. You can know the liquid flow rate gauging using a magnetic field. The conductive liquid flow through a magnetic field creates a voltage signal. The voltage which is created is relative to the motion of the flowing fluid. Thus, the electronic transmitter senses liquid by getting the voltage signal.

You can use magnetic sensors to gauge any conductive liquids. Yeah! Any conductive liquid you can think of. These liquids include acids, water, and slurry. The sensor has the lead of not blocking the fluids they gauge.

Always be careful when using magnet sensors in vacuum service. That’s because some sensor liners may collapse in a vacuum. The collapse causes damage to the flow meter.

Variable area flow sensor

It uses the system of a tapered tube and float. Variable area sensors work on a variable that is a system of cones and float. A flowing liquid changes the float or piston position to create more area for the fluid to flow. The position of the piston float and vane shows the flow rate. It is versatile as it works for both gases and liquids.

The ease of technology leads to low cost. It also gives readings for low-pressure drops. The inferior margin of error is what gives it its popularity.

Mass Gas Flowmeters

These sensors are also known as mass airflow sensors. You use Mass gas sensors in the vehicle applications. They are used to measure the air’s mass getting into the air intake system. Mass gas uses the principle of measuring heat transfer from a heated surface to a flowing fluid.

As air passes through sensors, it reduces the heat in the connective wires. The wires reduce their electrical resistance. The heat difference gives the liquid flow rate readings.

Read more: How Does Pneumatic Valve systems Works?

Coriolis meter is also another type of mass gas meter that uses a moving gas inertia principle. The inertia causes the tube to twist. The degree at which it revolves is relative to the flow rate gauging.

Turbine flow sensor

The sensor uses volume changes. When a fluid passes through the turbine chamber, it causes the turbine blades to rotate. The turbine blades’ speed is relative to the flow rate gauging.

Turbine flow sensors come in various types depending on your uses. Do you need accurate flow rate gauging? Well, use a turbine flow sensor of your choice. The turbine sensor can endure high pressure as well as adverse heat conditions.

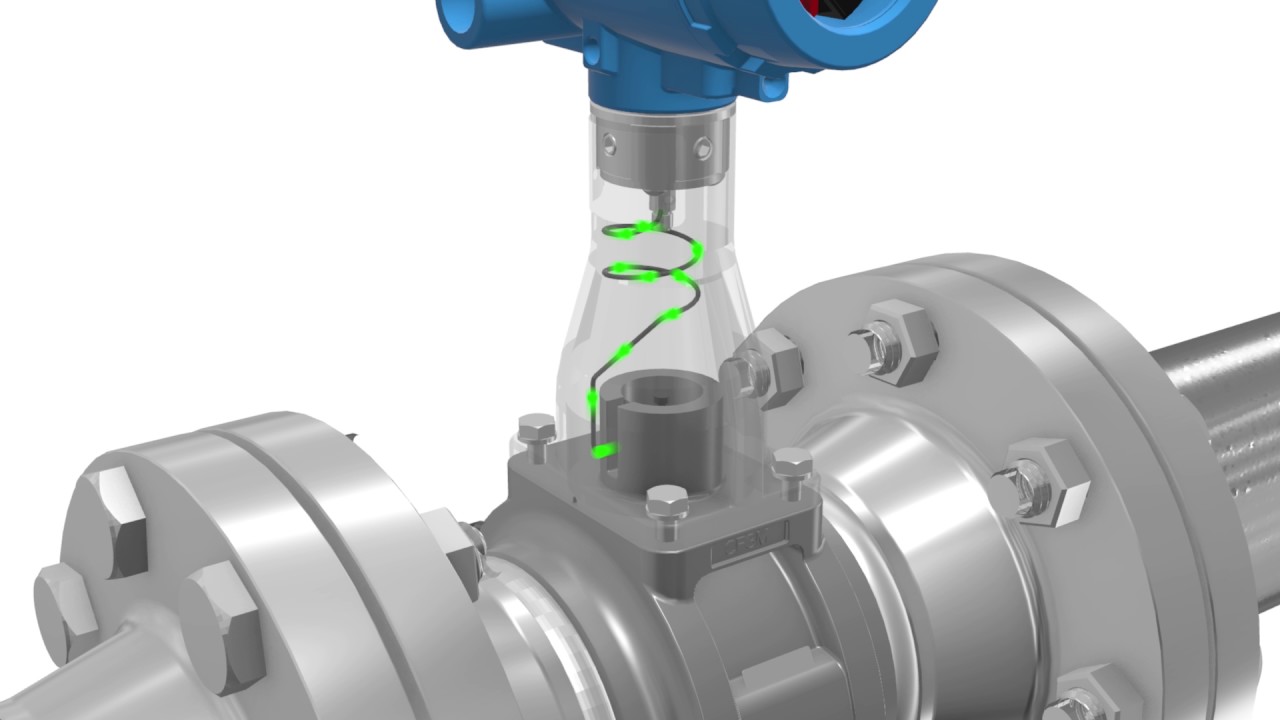

Vortex flow sensors

According to the Von Karman effect, the flow will generate whirls when passing by a bluff body. A bluff body is placed into the volume stream. Calculate the Flow rate gauge by multiplying the pipe area and the speed of the flow. The vortex sensors need straight upstream piping. That is to reduce uneven flow patterns. Whenever this is not possible, they use straightening veins.

Paddlewheel sensors

This sensor uses a simple design. It is also known as Pelton Wheel Sensors. Are you asking what these sensors entail? They have three main parts: a paddle wheel sensor, pipe fitting, and the display.

When the magnets in the blades spin past the sensor, the paddlewheels sensor creates a voltage signal. The speed and voltage signal is always relative to the flow rate gauging. The faster the flow of the fluid, the higher the liquid flow gauging. The paddlewheel sensor is created for use in a pipe fitting. It comes in various fitting styles, collection methods, and materials. They offer a low cost, higher accuracy option with liquids.

Final thoughts:

There are different flow gauging sensors as we’ve checked. You must know how a liquid flow sensor works to enable you to choose, depending on your need. The accuracy of the liquid flow measurement is as vital as the flow rate. Your choice of sensors shouldn’t be based on price only. Check other factors such as the liquid’s viscosity, type of pipes used, among other factors.

Leave a comment