You got many options for monitoring the flow rate of liquids, steam, and gases. Many devices have been developed and will always give you an accurate flow rate. If you are doing business that involves fluids, inaccurate data about flow rate may result in significant losses. That’s why you should explore the available flow meters and get the most suitable device to monitor your medium. In case you have made up your mind to buy a flow meter, get a Rotameter to help monitor the flow rate. It matters less whether you want to measure the flow rate of steam, gases, or liquid. Rotameter will always provide you will the most accurate flow rates.

How a Rotameter works?

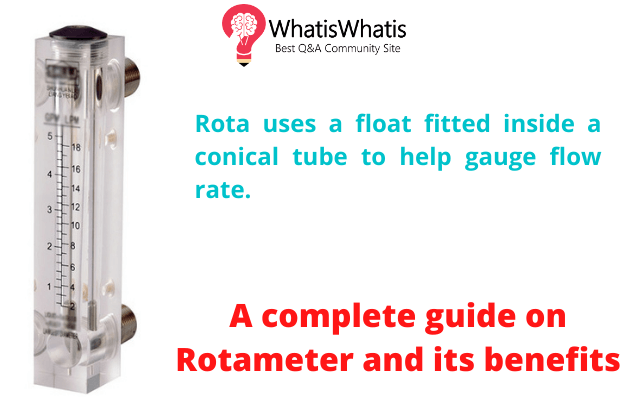

Rota uses a float fitted inside a conical tube to help gauge flow rate. The float is mobile and moves up and down freely inside the tube. Space is found between the float and the tube, but it is larger at the Rotameter’s top, which allows more fluid flow through the meter. The tube of the Rotameter is oriented vertically because gravity works in vertical alignment.

The gases, liquid, or steam to be measured flows in from the bottom of the Rotameter tube, moves upwards around the float, and then gets out through the top. A measuring tube is fixed vertically where its small end begins at the bottom of the Rotameter.

The float will always be resting on the dosing tube’s bottom if no flow is taking place through Rota. At that resting place, the diameter of the float will be the same as the inner diameter of your Rota tube.

If the flow begins and the fluid gets into the dosing tube, a floating effect makes the float lighter. But the float has a higher density than the liquid, and the flotation effect won’t be enough to raise the float.

See more: How To Choose the Best Thermal Flow Switches?

A small annular opening exists between the tube and float. When the pressure falling via float goes up, the float increases. That will then increase the space between the Rotameter tube and float to the extent that the upward hydraulic forces working on it get balanced by weight which is less the floating force.

To that point, the float will move up and down the Rotameter tube to the amount of fluid flow rate and the annular between the tube and float. When the equilibrium is reached, then the float and flow rate movement will have hit a stable position in the tube.

Suppose the float moves up to the larger end of the Rotameter conical tube, the annular opening between float and the tube increases. The pressure difference across float will also decrease with increasing area. Once that happens, the float takes on a dynamic equilibrium point if differences in pressure throughout the float and float effect balance with float weight.

What are the Rotameter types and their uses?

1. Glass tube Rotameter

You can use this device to monitor the flow rate of various fluids, both gases and liquids. In case you deal with fluid sampling, it’s the suitable flowmeter to use. You can rely on this Rota for accurate results in low flow measurements.

2. Armored purge Rotameter

Sometimes, the condition of the system may not be proper. In such a situation, this type of Rotaswings into action to purge the fluid. If you are looking for a device to use on corrosive applications, higher pressure fluids, and low flow rate, you got a great option with this Rotameter.

3. Fanged armored Rotameter

This is an ideal Rotameter you can use to measure non-conductive, opaque, and aggressive fluids in an industry. You can trust this device for accurate results if you are dealing with high-pressure applications.

What are the benefits of a Rotameter?

- Rotameter can offer some slight slurry service.

- You will get Rota that is viscosity- immune float.

- It’s ideal for the monitoring flow rate of corrosive fluids

- Rotameter offers a low-cost flow metering solution

- You can use Rota for small flow rates.

- It’s easy to install and cheap to maintain a Rota.

See more: Why Is Dew Point Important for Flow Sensors?

Problems associated with Rotameter

- Glass tubes can break beak.

- If you don’t install a Rota in a vertical position, it won’t work.

- You may face challenges seeing float when monitoring opaque fluids.

- A Rota needs a specific minimum flow rate magnitude. When the fluid flow rate goes below that minimum level, the float will fall and stick to your Rota device, affecting functioning.

Where to apply Rotameter meter?

- Process industries

- Monitoring gas flow in plants

- Measuring water flow in the industry.

Conclusion

A Rota device offers an economical solution to flow measurement issues. Make sure you get information about various types of Rotameter before buying. That will help you choose the suitable device based on the medium you seek to monitor. Whether you intend to measure the flow rate of chemicals or water, a Rota will offer you accurate results.

Leave a comment